Coating System for Float Glass

A highly-controllable, uniform spray for your float glass process. Ideal for antistain and other protective coatings.

- Virtually no overspray and no mess

- Low maintenance - ultrasonic nozzles never clog

- Drip-free spray

- Proven reliability for 24/7 manufacturing operations

- On-the-fly width control

Sono-Tek's experience and understanding of the unique demands of continuous float glass production has contributed to making the Widetrack spray system superior for the needs of the industry. It's proven reliability and low maintenance design make it excellent for 24/7 glass manufacturing processes.

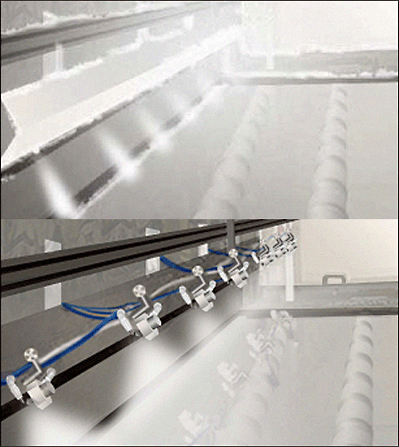

The illustrations on the left depict glass manufacturing using conventional spray methods (top)versus Sono-Tek's Widetrack system (bottom). The difference is dramatic. The amount of waste is greatly reduced, saving material and minimizing the release of material into the atmosphere, which promotes better environmental conditions as well as lowering risks to employees’ health. The resulting benefits of Sono-Tek’s low-velocity ultrasonic technology saves cost in materials, maintenance, exhaust requirements, and is beneficial in attaining and retaining ISO 14001 compliance. For more information on ISO 14001, visit www.iso.org

Total Customer Support

Sono-Tek has been

developing and manufacturing a wide range of quality products based on our

patented ultrasonic spray technology for more than 30 years. Each Widetrack

System is configured and factory tested specifically for each application.

Installation at your facility will be performed by our experienced field service

staff who will work with you to set up your process and train your production

and service personnel. After installation, we are available for consultation on

service, process setup, or system operation.

- Slide out modular design provides easy access to electronic modules

- No heat build-up despite the high temperatures associated with float glass production

- Pump control system delivers repeatable flow to each nozzle

- Integrated air conditioning system keeps electronics cabinet cooled

- Real time monitoring of all system functions

- Control tower with full PLC control using 19" touch screen HMI

- Line speed encoder for continuous monitoring of process

Operating Principle

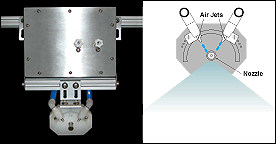

Each spray assembly contains a pair of air jets which alternately pulse to drive the spray downward. The timing and force of the pulses produces a spray pattern that oscillates back and forth across the substrate.

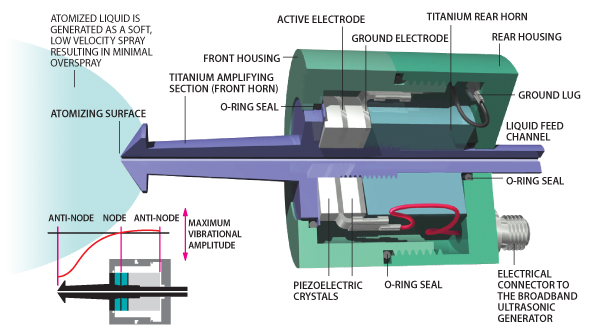

Liquid Atomization

.: Weblog Themes By Pichak :.