برنامهای هوشمندانهتر برای تولید برق؟

اگر در بیابانهای غرب آمریکا رانندگی کنید، ممکن است با منظرهای جدید روبهرو شوید: صدها هکتار پنل خورشیدی که برای تولید برق نصب شدهاند. از یک نظر، این عالی است — ما داریم از انرژی پاک در جایی استفاده میکنیم که پیشتر فعالیتی وجود نداشت.

اما بیایید کمی دقیقتر نگاه کنیم: حتی این مناطق بهظاهر خالی نیز ارزش زیستمحیطی دارند. تبدیل آنها به سایتهای صنعتی همچنان تبعاتی برای محیطزیست دارد.

پس راه بهتر چیست؟

در آمریکا، تنها از طریق نصب پنل خورشیدی روی پشتبام خانهها میتوان تا ۴۵ درصد از نیاز برق کشور را تأمین کرد. این سامانهها کمهزینهتر، قابلنگهداریتر هستند و نیاز به زیرساخت جدید ندارند. و بیایید واقعبین باشیم — ما به شدت به تولید بیشتر برق نیاز داریم.

پس چرا دولتهای محلی حمایت جدیتری از این گزینه نمیکنند؟ این سوال بهجاست. بهخصوص وقتی انرژی ارزان یکی از کلیدهای رشد اقتصادی است.

وقت آن است که در مورد محل و روش تولید برق تجدیدنظر کنیم.

#خورشیدی #گذار_انرژی #برق #انرژی_پاک #تولید_غیرمتمرکز

|

Evaluating a glass slice in cross-section to verify surface compression and mid-plane tension is a highly recommended QC practice. Strainoptics offers two polarimeter systems designed for this application, the PS-100-MW Polarimeter and the DIAS-1600 Digital Image Analysis System. PS-100-MW Polarimeter. Supplied with a 75mm high-intensity light source, a microscope and a measuring wedge assembly.

|

The DIAS-1600 Digital Stress Analyzer is a machine-vision, PC-based workstation for off-line stress inspection. Measurement results are reported for individual points, as graphs of stress vs. position along any line, or as full-field color-coded quantitative stress maps. Use of the DIAS-1600 provides the following benefits:

|

ادامه مطلب

اسکنربرای اندازه گیری تنش شیشه انلاین

|

To ensure optimum cutting performance, we recommend measuring stress in cross-sectionthrough the thickness of the glass. NEW! PS-500 On-Line Visual System for monitoring

|

The SCA-1500 on-line float glass stress scanner automatically measures and reports residual stress across the glass ribbon at the cold end of the float line. It features user-friendly PC-based operation, and requires no special operator skills or training. Field-proven technology and reliability have made the SCA-1500 the choice of the world's leading primary glass manufacturers.

|

ادامه مطلب

Zippe Batch Preheater brings energy savings

Glass production is an energy intensive process, where fossil energy, necessary for the melting process, is emitted to the atmosphere.

To reach climate protection targets and reduce energy costs, the glass industry is striving for an energy efficient glass production process.

The aim is to optimise the glass production process in a way that reduces energy consumption as much as possible.

The industry has optimised many process steps regarding but in the area of the rejected heat by the waste gases there is still plenty of thermal energy, which ends up unused in the atmosphere.

The solution

Zippe works in the field of batch preparation and cullet handling, among other things. It built its first batch preheaters several years ago with a high recycling cullet portion and sold them successfully.

It has developed its preheating technology and adapted it to the different batch formulas of the single glass types thanks to its collected experience. Preheaters that run independently from the cullet portion are also now available.

For the operator of a production process it is necessary to follow-up the process steps integrally, starting with the entrance of the raw material up to the outgoing of the final product and to optimise the corresponding processes in a way that a maximum of productivity is reached with the least effort regarding raw materials and waste material.

Therefore Zippe always observes the whole process in its field of activity in the glass industry and tries to plan the different cycles energy efficient, low-maintenance and this inexpensive for the operator.

The advantages of batch preheating are:Reduction of emissions (CO2 and NOx), increased energy efficiency and increased plant productivity.

برچسبها: پیشگرم کن بچ, مواد اولیه, شیشه تولید شرکت زیپه

سيستم بابلر يا حباب ساز:

در كوره هاي شيشه به منظور1-بهبود جريان هاي جا به جايي به صورت اجباري

2-بهبود دماهاي كف و همزدن مذاب در زمان توليد شيشه رنگي

3-بهبود كيفيت شيشه

مورد استفاده قرار مي گيرد

برچسبها: سيستم بابلر يا حباب ساز در زير كوره هاي شيشه

Despite the

fact that stable production of high quality products requires close

control of all aspects of the process, beginning with the raw materials

and ending at the cold end, one part of the process does not always

receive the attention that it deserves - the charging of the batch into

the furnace. Batch charging can have a significant influence on melting

rate, glass quality and furnace life, all of which are of major

economic importance for the operating company. |

Requirements RequirementsFrom the points of view of the furnace designer and operator there are four main areas which must be considered:

The “melting” process actually comprises a complex combination of melting and chemical reactions, during which some components are dissolved rather than melted. These reactions take place at high temperatures. Unmolten batch is a good thermal insulator, and therefore heat transfer within a pile of batch is relatively poor. It can be difficult to raise the temperature in the centre of a pile to that required for the processes to take place, and as a result unmolten batch can be transported a long way into the furnace. The best way to avoid this problem is to limit the thickness of batch piles, maximise the surface area available for heat transfer, and to cover as much as possible of the bath surface of the melting end with batch. These factors are determined largely by the batch charging technology used. Large unbroken strings of batch should be avoided, as should an overall blanket without gaps. Glass quality Batch charging can affect glass quality when, for example, unmelted batch is propelled towards the front of the furnace and into the refining area. It may then be pulled into the extraction current and appear in the product as stones or cords. This risk is increased if batch “logs” are produced which can be easily pushed along the furnace. Charging in more than one direction can help to alleviate this problem. Although not directly connected with the batch charging function, the flame and booster and bubbler systems can also exert an important influence on the movement of batch in the furnace. Refractory corrosion Batch is both cold and mechanically abrasive, and contact between batch and refractories can result in substantial wear on the refractories. Chargers that do not use a doghouse, such as screw chargers, often produce a large pile of batch directly in front of the charging position, which is in contact with both superstructure and tank refractories. In end-fired furnaces with a single doghouse attempts to avoid long batch logs moving quickly down the furnace can result in the tendency to charge slightly backwards, towards the rear wall. This can lead to the batch piles literally “bouncing” off the rear wall at a shallow angle and then going on to contact the side wall opposite the doghouse, resulting in accelerated wear of the tank refractories at both contact points. Doghouse design The installation of a doghouse on a furnace produces several disadvantages. During the heating up it is difficult to control the refractory expansion in the doghouse area. During operation the doghouse increases energy losses, in many cases it allows the uncontrolled entry of induced air, and it is often subject to heavier refractory wear so that it may become a weak point in the furnace structure during the later part of the furnace campaign. Nevertheless, a doghouse allows the use of those charging systems that can influence the pattern of the batch distribution on the surface of the glass bath, which in turn can have a positive effect on achievable melting rate and on glass quality. It also provides a relatively “quiet” area in the superstructure where pick-up of fine batch components is limited, thus reducing carryover and subsequent build-up of solid material in regenerators and waste gas channels. The design of the doghouse must suit the characteristics of the batch charger to be used, and should minimise contact areas between cold batch and the tank refractories in order to limit wear. Radiation losses should be reduced as far as possible by limitation of the size, and the superstructure should be sealed as effectively as possible to restrict the ingress of cold air. Types of charger A number of different types of charger are used to fulfil these requirements. The main types are described below using the chargers supplied by EME Maschinenfabrik Clasen as examples. Screw charger This design comprises a horizontal metallic screw located within a cylinder, which is inserted through a hole in the superstructure side wall. Batch falls into the screw by gravity and is transported into the furnace by the movement of the screw. Charging quantity variation is made by varying the rotation speed of the screw. The construction does not need a doghouse, and can be installed in a simple opening in the superstructure. This means that it is easy to seal around the charger and prevent the uncontrolled ingress of cold air. However, the principle has a range of disadvantages. A water-cooled mantle is required around the cylinder to protect the material from the high temperatures in the furnace. This can cause damage to the superstructure refractory in the charging area. The charger pushes batch into the furnace, but it does not have any influence on the form or size of batch piles in the furnace, or on their movement. As the batch is not moved away from the charging area by the action of the charger there is a high level of contact between cold batch and the refractory adjacent to the charger opening, both in the superstructure and the substructure, and this can lead to extensive damage to these refractories. Finally, the use of cullet is limited, as it results in high wear levels on both the screw and the jacket.  Figure 1 – screw charger Piston charger The piston charger is similar in many ways to the screw charger, but the screw is replaced by an oscillating piston which is used to push the batch into the furnace. The advantages and disadvantages are also similar to those of the screw charger. However, the piston charger is only suitable for very fine batch materials, and cannot be used when cullet is included in the batch. Blanket charger (Type SB) This type of charger requires a doghouse, as the material is fed onto the glass bath surface. The basis of this type of charger is an inclined tray situated below the outlet of the batch hopper. The tray is moved backwards and forwards more or less parallel to the plane of the tray bottom. As it moves forward the batch contained in the tray also moves forwards, as does the batch floating on the glass bath in front of the charger. As the tray moves backwards the batch in the tray is prevented from moving backwards by the downward slope of the tray and the column of batch emerging from the hopper. The space created at the rear of the tray by the backwards movement is filled by material dropping by gravity from the hopper. The tray then moves forward again, and the cycle is repeated. The basic principle is shown in figure 2 below.  Figure 2 – basic principle of the blanket batch charger The rate of charging is changed by varying the speed of movement of the tray or by switching the movement on and off. The stroke of the tray movement is a further variable which can be used to influence the charging pattern, but this cannot be adjusted on the run. This type of charger does influence the movement of the batch away from the doghouse, in that the forward movement of the tray pushes the batch piles outwards. However, because the feed and forward pushing effect are combined, this effect stops whenever the feed is interrupted. When there is no feed there is no movement of the batch, except that which occurs as a result of the extraction current in the glass, and this is very slow. Therefore, this type of charger does not break up the batch into individual piles, but, as the name suggests, it produces a closed batch blanket. Side-port furnaces are charged from the rear side and the doghouse can be made almost as wide as the furnace itself. A number of blanket chargers can be installed alongside one another, and the combination provides very good coverage of almost the complete glass bath surface. In this case, the fact that the batch piles tend not to be broken into smaller individual piles is compensated by the large area which is covered. This is a typical arrangement in large float tanks. The large doghouse required by the blanket charger is particularly difficult to seal.  Figure 3 – the EME type BS blanket batch charger Enclosed doghouse pusher charger (Type ESE) This type of charger comprises a water cooled pusher located underneath a small feed hopper. The pusher is curved and is pivoted so that it moves in an arc through an angle of approximately 45°. When the pusher is in the rear position the opening of the feed hopper is open and batch can fall onto the surface of the glass bath. As the pusher moves forward this batch is moved into the furnace by the front face of the pusher, whilst the outlet of the feed hopper is closed by the pusher body. As the pusher moves back the feed hopper outlet is opened again, fresh batch falls into the space left by the batch which has just been moved away and the cycle is repeated. The charging rate is varied by altering the pusher speed, or by switching the movement on and off. Manual adjustment of the pusher stroke is available and the flow rate from the feed hopper can be varied by means of a slide. The feed and pushing action are combined, and therefore there is no forwards movement of the batch when the feed is stopped. As a result it is difficult to break up the batch into individual piles, especially at higher loads. An improvement can be obtained when the charger is swivelled to the left and right by about 5 -10° to enable charging to take place in different directions. This type of charger is very compact, and actually sits on top of a small doghouse. The charger is surrounded by water cooled boxes which are in contact with the refractory and require a large volume of cooling water. The design offers a completely sealed doghouse.  Figure 4 – the EME type ESE closed doghouse pusher batch charger Pusher charger (Type CPO) In this design of charger the feeding and pushing operations are separated. Batch is fed onto the surface of the glass in the doghouse by a vibrating chute located below the feed hopper. The batch is then pushed forwards by a water cooled pushing arm, which traces an elliptical path in front of the end of the vibrating chute. The basic principle is shown in figure 5 below.  Figure 5 – basic principle of the pusher batch charger The charging rate is determined by the vibration speed of the chute, which is independent of the movement of the pusher. It is therefore possible to continue the pushing action after the feed has stopped, and in this way individual batch piles can be created. The pusher movement offers a number of variables that can be used to influence the charging pattern. These are the stroke, speed and depth of immersion. This type of charger is often provided with a swivelling action so that batch is charged in two or three different directions. This also helps to distribute the batch over more of the glass bath surface and is especially useful in the case of large end-fired furnaces. The introduction of the two mechanical elements – the chute and the pusher arm – into the doghouse superstructure, and the shape of the movement of the pusher, make it difficult to seal the doghouse. A removable hood seems to offer the best solution, but the sealing is incomplete.  Figure 6 – the EME type CPO pusher batch charger Conclusions A number of factors must be taken into account when the best type of batch charger is chosen for a particular application. The choice may be complicated by the fact that some of the requirements are contradictory. Doghouse sealing is an important aspect, especially in the case of oxy-fuel furnaces. Oxy-fuel firing is often used for special glasses, where low specific melting rates mean that the charging pattern may be less critical than in other applications. In addition, the cullet ratio used is often low. Therefore the screw charger may be a very suitable solution. Side-port furnaces offer the advantage that the doghouse can be installed on the rear wall and, if needed, it can be made almost as wide as the tank, thus allowing charging over the complete width of the furnace. The blanket charger is well suited for this type of application, as demonstrated by the typical arrangement found on float furnaces. Large, high capacity end-fired furnaces, especially those with high specific melting rates, are particularly dependent on the batch charging technology used. In such cases the charging flexibility offered by the pusher design cannot be bettered, and today, this design of charger is the type most commonly used on such furnaces. Richard Sims - Nikolaus Sorg GmbH & Co KG www.sorg.de |

برچسبها: مروري بر انواع بچ شارژرهاي مورد استفاده در صنعت شي

عيوب نهايي در محصول توليدي گاها مي تواند براي مصرف كننده خطرناك باشد فلذا در خط توليد نياز به يك سيستم عيب ياب است كه يكي از شركت هاي مشغول در اين زمينه ايريس است

http://www.iris-im.com/-glass-defects-inspection-.html

برچسبها: سيستم عيب يابي براي خط توليد شيشه, http, www, iris

Molybdenum stirrers.

|

|

Fully platinum-plated stirrers.

| With its excellent creep resistance and stability at high temperatures, molybdenum ensures the necessary mechanical stability, while the soft platinum cladding guarantees optimum resistance to corrosion. |

|

Partially platinum-plated stirrers.

| Molybdenume glass and opal glass melts, molybdenum is exposed directly to the glass melt without any problem. Our partially platinum-plated stirrers are used for this task. Only the stirrer shaft outside of the glass melt is protected against oxidation by means of a platinum cladding. |

|

برچسبها: همزن هاي موليبدن مقاوم در برابر خوردگي در صنعت شي

ادامه مطلب

برچسبها: ماشین آلات مربوط به خط شیشه بطر, جارو, شامل IS, کوتینگ و

ادامه مطلب

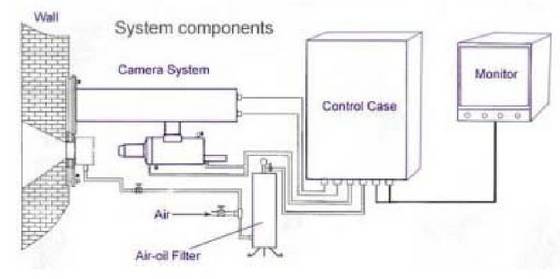

برچسبها: مشخصات یک دوربین برای فیلم برداری و عکس برداری ازد

ادامه مطلب

Water Jets |

|

|

|

|

H-800(Improved) arc-edge polishing machine |

YD-2015 series water jet cutting machine |

|

|

|

YD-250 CNC Machining Centre |

YH-800 (Export) arc-edge polishing machine |

برچسبها: سیستم واترجت برای برش شیشه شرکت

ادامه مطلب

|

|

|

BP23 |

BP24 |

|

|

|

BP25 |

BP26 |

|

|

|

BX1-A |

BX1-B |

|

|

|

BX1-C |

BX1-D |

Cutting Glass Tools |

|

|

|

|

BX2-A ADJUSTABLE ANGLE SUCTION PLATE |

BX2-B ADJUSTABLE ANGLE SUCTION PLATE |

|

|

|

BX2-C Right angle glass suction plate |

Cicle and Oval Cutting Machine |

|

|

|

Circle Cutter BLD (R) |

Circle Cutter BLD (R)B |

|

|

|

Glass Cutter (Copper) |

Glass Cutter (Plastic) |

ادامه مطلب

|

||||||||||||||

| All Automatic Suspended Top Roll | ||||||||||||||

适用范围

<'%=rs("note")%>

-->

Product ID: 8114212314 Product Name: All Automatic Suspended Top Roll Product Category: Automatic hang-pull machine Clicks: 946 >> Details

|

ادامه مطلب

|

||||||||||||||||||||||

| Large Leaning Blanket Batch Charger | ||||||||||||||||||||||

适用范围

<'%=rs("note")%>

-->

| ||||||||||||||||||||||

| |||||||||||||||||||||

ادامه مطلب

1. Glass thickness:1.0~25mm

2. Length of top-roller rod (Max.):3400mm

3. Linear speed of collet:10~1500m/h

4. Front and rear adjustable travel path:3000mm

5. Collet horizontal swing angle:±19°

6. Emergency lifting-up height:90mm

7. Top roller rod movement, up & down and horizontal:100mm

8. Collet diameter run-out:<0.2mm

9. Specifications subject to the customers’ requirement

Two Types of Top Roller:

Suspended Type

Console Type

Basic motions:

Each top roller has five movements that can be separately

operated and controled.

ادامه مطلب

Cross Cutting Machine:

Technical

Specification :

Technical

Specification :

Glass thickness:2~19mm

Max. glass width:4500mm

Glass length:600~1000mm

Cutting Accuracy

Cutting linearity:+/-0.8mm

Max. tolerance of diagonal dimensional:+/-1.5mm

Max. speed of glass running:3000mm/S

Permissible glass swing range: +/-200mm

1、Cutting

pressure can be adjusted steplessly.

2、Adoping human-machine interface for an intellectual control system.

3、Cutting dimension and quantity are input by means of keyboard

and displayed on screen.

4、The control system enables the cross cutting machine to have the

function of alternative cutting with four different lengths(sizes)

of glass sheets.

5、Two cutters on two bridges can be alternatively as standby and

can also be operated simultaneously.

ادامه مطلب

ongitudinal Cutting Machine: |

|

ادامه مطلب

.: Weblog Themes By Pichak :.

Pressure regulation:0

Pressure regulation:0