• نانوکامپوزیت ها

مواد کامپوزیتی مواد مهندسی ای هستند که از دو یا چند جزء تشکیل شده اند به گونه ای که این مواد مجزا و در مقیاس ماکروسکوپی قابل تشخیص هستند. کامپوزیت از دو قسمت اصلی ماتریکس(زمینه) و تقویت کننده(پرکننده) تشکیل شده است. ماتریکس با احاطه کردن تقویت کننده آن را در محل نسبی خودش نگه می دارد و تقویت کننده موجب بهبود خواص مکانیکی ساختار می گردد.

یکی از گسترده ترین کاربردهای فناوری نانو در صنعت خودرو تا کنون ساخت نانو کامپوزیت ها بوده است. از آنجا که در نانوکامپوزیت ها، ذرات بسیار ریز (نانوذرات)، استحکام و دوام رزین را بسیار بالا می برند، جایگزین مواد مرسوم مانند میکا و تالک شده اند. اما علاوه بر ویژگی های فیزیکی بهتر، این کامپوزیت ها دارای دو برتری دیگر نیز می باشند:

نخست اینکه نانوذرات با ایجاد ماتریکس (زمینه) یکنواخت و هموار به طور قابل توجهی زیبایی بیشتر را فراهم می کنند و بنابراین نانو کامپوزیت ها سطح زیبا تر و رنگ های شفاف تری دارند.

همچنین نانوکامپوزیت ها به دلیل نیاز به مواد تقویت کننده ی کمتر، تا حدود بیست درصد نسبت به کامپوزیت های رایج سبک ترند.

• اثر نیلوفری و کاربرد آن در ساخت سطوح خود تمیز شونده

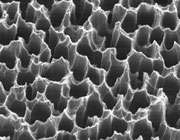

یکی از شناخته شده ترین مزیت های فناوری نانو اثر نیلوفری ست که سطوح خود تمیز شونده را امکان پذیر می سازد. به سبب ساختار بسیار صاف و یکنواخت سطح گل نیلوفر، قطرات آب و گرد غبار از روی گلبرگ ها می لغزند بی آنکه اثری روی آنها به جای گذارند.

بنابراین اگر سطوح اجسام دارای ساختار بسیار صاف و صیقلی (در مقیاس نانو) باشند، ذرات آلودگی و همچنین آب روی آنها باقی نخواهد ماند.

رنگ ها و پوشش های سقف خودرو که این اصل طبیعی را به کار می برند امروزه در بازار موجود می باشند. ساختار نانویی این سطوح، از جمع شدن ذرات آلودگی و قطرات بسیار ریز آب نیز جلوگیری می کند. همچنین رینگ های خود تمیز شونده نیز با استفاده از این ویژگی در حال تولید هستند.

همچنین

پوشش نانویی در حال تولید است که با اضافه کردن آن به سطح شیشه خودرو

(برای مثال به روش اسپری کردن)،فرورفتگی های بسیار ریز سطح شیشه را پر

کرده و سطح صاف و بدون پستی و بلندی ایجاد می کند و در نتیجه قطرات ریز آب

و گرد و غبار روی شیشه باقی نمی ماند و بنابراین موجب افزایش دید راننده،

استهلاک کمتر برف پاکن ها و نیاز کمتر به شستشوی شیشه و همچنین بهبود دید

در شب در نتیجه کاهش انعکاس مضر نور می شود.

• شیشه های نوین با توانایی بازتاب پرتو فروسرخ

نمونه ای دیگر از کاربرد های نانوفناوری در صنعت شیشه خودرو، شیشه هایی با قابلیت بازتاب پرتو فروسرخ نور خورشید می باشد. به این گونه که یک لایه بسیار نازک از نانوذرات بین دو لایه ی شیشه قرار گرفته اند که وظیفه آنها بازتاباندن پرتو فرو سرخ نور خورشید و در نتیجه جلوگیری از گرم شدن زیاد داخل خودرو می باشد.

برچسبها: نانو در صنعت شیشه

اخيراً از ميان کاربردهاي گسترده نانولولههاي کربني، لايههاي رساناي شفافِ نانولولهاي، بيشترين نگاهها را به خود معطوف کردهاند. اين مواد در صفحات نمايش تخت، صفحات نمايش تماسي، نورافکني حالتجامد و پيلهاي خورشيدي کاربرد دارند. از سوي ديگر، نياز به ساخت ابزارهاي داراي مصرف انرژي کمتر و استفاده از انرژيهاي جايگزين، تقاضاي جهاني براي لايههاي رساناي شفاف را شدت بخشيده است.

هماکنون براي کاربردهاي رساناي شفاف غالباً از اکسيدِ ايندوم قلع استفاده ميشود، اما به دليل کميابي ايندويم، با افزايش تقاضا در ۵ سال اخير هزينههاي مربوط به اين کاربردها افزايش يافته است. از سوي ديگر، اينديوم براي کاربردهايي چون LEDها و ابزارهاي فتوولتاييک مناسب نيست.

گروه ذکر شده براي يافتن يک رساناي شفافِ جايگزين، گام مهمي برداشتهاند. آنها با به کارگيري يک روش جديد که سانتريفوژِ سريعِ شيبِ غلظت (density Gradient ultracentrifugat ion ناميده ميشود، نانولولههاي کربنياي با خصوصيات نوري و الکتريکي يکنواخت، توليد کردهاند. لايههاي نازکي که با استفاده از اين نانولولههاي بسيار خالص ساخته مي شوند، نسبت به مواد نانولوله کربني موجود، ۱۰ برابر رساناتر هستند.

علاوه بر اين، در روش جديد، نانولولههاي کربني بر اساس خصوصيات نوري خود مرتب ميشوند و اين مسئله، امکان ساخت لايههاي رساناي نيمهشفاف را در رنگهاي دلخواه، فراهم ميآورد. به همين دليل مواد مذکور شبيه شيشههاي رنگدار هستند. البته بر خلاف اين شيشهها، لايههاي نازک نانولولهاي بسيار رسانا بوده و به دليل انعطافپذيري بالا، بر خلاف اينديوم، براي کاربردهاي فتوولتاييک مناسب هستند.

مارک هرسام، سرپرست گروه مذکور که پروفسور علم و مهندسي مواد در دانشگاه نورسوسترن است، در اين باره ميگويد: «در دنياي مدرن، رساناهاي شفاف کاربردهاي بسيار زيادي دارند. لايههاي نازک نانولولهي کربني خالص، علاوه بر اينکه قابليت تسخير کاربردهاي فعلي را دارند، ميتوانند توسعه فناوريهاي جديد مانند LEDهاي آلي و ابزارهاي فتوولتاييک آلي را تسريع کنند».

نتايج اين بررسي در نشريه Nano Letters به چاپ رسيده است.

برچسبها: ساخت شيشه انعطافپذير و رساناي رنگي با استفاده از

Ion exchanged glasses are made for several different purposes, e.g. chemical strengthening, colouration and optical waveguides. Chemically strengthened float glass is considerably more expensive to produce than thermally strengthenened, but will likely find applications in future building and interior constructions where strength demands, design and shape prevent the use of thermal strengthening. The aim of the presented work is to study ion exchange processes on float glass surfaces. In longer terms, the chemical strengthening is planned to be applied to specific critical area e.g. around a drilled hole which without treatment deteriorates the overall strength of the glass. In this study, the less frequently studied approach single-side ion exchange of different ions of commercial float glass is described. The concentration vs. depth profiles were determined either by the use of the Surface Ablation Cell (SAC), which allows the continuous removal of the material from a flat glass surface by slow controlled isotropic dissolution. The results show that similar diffusivities and concentration vs. depth profiles are achieved with single-side ion exchange as from the traditional way of immersing glass in molten salt bath. Ion exchange of Ag+ stains the float glass on both sides giving it a yellow or amber-brownish colour. Unlike Ag+ ion exchange of Cu+ stains the float glass on the tin-side only, giving it a yellow, red or red-brown colour. Determining the concentration vs. depth profiles of ion exchanged float glasses with the SAC was convenient except for Ag+ which was determined with SEM-EDX. The work confirms that the procedure and equipment of the SAC are cheap, easy to use and gives data similar to those gained by other surface analytical techniques. The Calculated diffusion coefficients of K+, Ag+ and Rb+ are in accordance with literature data while Cu+ and Cs+ diffusion coefficients were slightly lower. The diffusion coefficients of the different ions follow the order Ag+>K+>Cu+>Rb+>Cs+ and ranges between 9.4E-10 and 4.8E-13 cm2s-1. The calculated activation energies for diffusion of K+, Ag+ and Cu+ corresponds with reported literature data and were calculated to: Ag+(air-side) 152 kJ/mol, Ag+(tin-side) 185 kJ/mol, K+ 108 kJ/mol and Cu+ 115 kJ/mol.

ادامه مطلب

درقرون سطی صنعت کاران شیشه گر شیشه رنگی زردی رااز نوع سودالایم با مخلوطی از نمک های نقره ترکیب خاک رس و روغن های طبیعی ساختند

ادامه مطلب

A

PROCESS TO RECYCLE THIN FILM PV MATERIALS

Robert E. Goozner, William F. Drinkard, Mark O. Long and Christi M. Byrd

Drinkard Metalox, Inc., 2226

N. Davidson Street,

Charlotte, NC

28205

26TH IEEE PHOTOVOLTAIC SPECIALISTS CONFERENCE

ANAHEIM CALIFORNIA

29 SEPTEMBER - 03 OCTOBER 1997

ABSTRACT

INTRODUCTION

There is wide scale interest in the commercial potential and wide scale use of cadmium and cadmium telluride (CdTe) and copper indium diselenide (CIS) photovoltaic modules. These type of thin film devices have demonstrated advantages which include good performance, the ability to be manufactured by various methods and apparent environmental stability. There are currently several efforts underway in the United States and abroad to manufacture thin film PV modules and commercialize them. The use of these modules would entail the use of toxic metals such as cadmium, selenium and (potentially) lead in their manufacture. The manufacture of thin film photovoltaic modules, as in the manufacture of any article, must address the associated environmental safety and health issues, as has been reviewed by P.D. Moskowitz et al. [1]. Government agencies, industry groups and private citizens will be placing greater emphasis on the requirement that emerging technologies will not endanger health, safety or the environment. This problem will become more acute in the future as large scale thin film photovoltaic production generates appreciable waste streams and superannuated photovoltaic modules. Cadmium and selenium continue to be regulated because of their toxicity. Since these metals are regulated in other industries, national standards must also be met in the manufacture of thin film photovoltaic modules.

An important problem in the field of photovoltaic (PV) technology is that there has been no process specifically designed to remove and recycle the metals in an environmentally benign fashion. The range of metals which can be present in thin film PV devices may include cadmium, copper, lead, gallium, indium, selenium and tellurium. The substrates they must be separated from are glass, plastic or similar low cost substrates.

|

Table 1. TCLP Results For PV Cells |

||||

|

Source |

Description |

Cd (mg/L) |

Se (mg/L) |

Pb (mg/L) |

|

#1 |

CdTe Laminate |

0.915 |

- |

0.038 |

|

#2 |

CIS Circuit |

0.079 |

0.283 |

37.5 |

|

#2 |

CIS Laminate |

0.098 |

0.404 |

0.503 |

|

#2 |

CIS Plates |

0.016 |

0.419 |

0.073 |

|

#3 |

CIS Plates |

0.213 |

0.254 |

0.107 |

|

#4 |

Si Laminate |

- |

- |

5.3 |

|

#4 |

Si Module |

- |

- |

6.5 |

|

EPA LIMITS |

1 |

1 |

5 |

|

The results in Table 1 show that the levels of Cd and Se are within current TCLP limits, although the Cd level for the CdTe cell is close to the limit. Repeated testing of CdTe cells will probably yield some results above the TCLP limit. An elevated level of lead was observed for the CIS cells. Further examination showed that this was from a lot of hand soldered prototypes, indicating that the method of mounting the PV laminate in the finished module (especially if lead containing solder is used) should always be evaluated. As a comparison, the TCLP results for Silicon PV cells showed TCLP levels slightly above the EPA limits of 5 mg/L for lead when both the laminate and complete module are tested. Although there are a number of ways that lead can be removed by leaching and precipitation processes, the utilization of lead free solder and solder free electrical connections should be considered for the manufacture of PV modules.

METAL RECOVERY PROCESSES

Alternative processes have been developed for the recovery of metals from scrap and superannuated CdTe and CIS modules. These processes are presented below.

CdTe CELL PROCESS

Figure 1 shows a process to recover metals from scrap CdTe modules.

The treatment process in Figure 1 is to treat the CdTe cells with a nitric acid based lixivant. This lixivant selectively oxidizes and solubilizes the Cd and Te while leaving the SnO2 conducting layer intact on the glass substrate. This will enable the reuse of the substrate in the manufacture of PV cells. Separation of the substrates from the lixivant separates out the Cd and Te. The lixivant is reused to process cells until a high Cd and Te loading is attained. Metal loadings in excess of 100 grams per liter are achievable. The subsequent treatment of the pregnant lixivant is to electrolyze the material with DC current. Proper selection of the current and electrode materials enabled the precipitation of tellurium metal on the cathode while leaving the cadmium in solution.

CIS CELL PROCESS

The processing of CIS cells can be considered to be more challenging due to the wider assortment of metals in these cells. The metals present in CIS cells can include copper, indium, selenium, cadmium, zinc and additionally lead from the electrical connections. This different assortment of metals (as compared to CdTe cells) led to the development of the recycling process outlined in Figure 2.

The treatment process in Figure 2

is to treat

the CIS cells with a nitric acid based lixivant. This lixivant

selectively

oxidizes and solubilizes the Cu, In, Se, Zn and other metals from the

substrate

while leaving the SnO2 conducting layer intact on the glass

substrate. The EVA plastic from the laminate will be hydrolyzed and

float to

the top of the lixivating solution where it can be retrieved for

disposal,

since the EVA plastic passes TCLP and requires no further treatment.

The

subsequent treatment of the pregnant lixivant is to electrolyze the

material

with DC current. Proper selection of the current and electrode

materials

enabled the two stage deposition of metal: the first being a Cu/Se

mixture and

the second being the residual cadmium. Electrolysis results for the

separation

of Cu/Se from Cd are shown in Table 2.

|

Table 2. Electrolysis Results For 10,000 ppm CIS Metals Solution. |

|||||

|

No. |

% Metals Removed From Solution |

||||

|

|

Cd |

Cu |

In |

Se |

Zn |

|

1 |

0 |

94 |

0 |

88 |

0 |

|

2 |

16 |

0 |

89 |

0 |

|

|

3 |

20 |

94 |

0 |

90 |

0 |

The results in Table 3. shows the selective separation of Cu/Se and Cd

on the

cathode while leaving the Zn and In solution. In full scale operation

the

electrolysis would be performed in a trough configuration having a

series of

electrodes, whereby the Cu/Se would plate out on the electrodes nearest

the

solution inlet and the Cd would plate out on the electrodes nearest the

solution outlet.

Oxidation and distillation of the Cu/Se mixture yields a pure SnO2 product. Decomposition of the lixivant will yield a mixture of indium, zinc and residual metal oxides which can be sold to a refiner or further treated via solvent extraction.

FURTHER WORK

Additional work is being performed on a combined CdTe/CIS recovery process and developing technology to combine these processes with current industrial selenium electrochemistry and cadmium processing technologies.

A pilot plant demonstration of the process on several barrels of PV waste will be performed during 1998.

ACKNOWLEDGMENT

REFERENCES

2. 40CFR Ch.1 Pt.261, App.II (7-1-91 Edition).

An oxy-fuel burner generates a long, luminous, stable and adjustable flame temperature profile flame by incorporating separate, fuel and oxygen jets oriented in a unique geometry. In one preferred embodiment, the fuel is injected horizontally at medium injection velocity (50-200 m/s) while primary oxygen is injected underneath the fuel jet at supersonic velocity (300-500 m/s). The supersonic velocity oxygen jet (20 to 50% required for stoichiometric combustion) entrains fuel and furnaces gases in it's core for the primary flame development over the furnace load. The subsequent mixing of the fuel, primary oxygen and entrained furnace gases establish a low NOx, stable, long and luminous primary flame. The secondary oxidant, preferably air or low purity oxygen (50 to 80% of stoichiometric needs), is injected above the flame using one or more oxygen jets to create an oxy-fuel flame with adjustable flame characteristics. The secondary oxidant completes unfinished combustion of flame gases containing CO, H

What is claimed is:

1. An oxy-fuel burner for producing a long, luminous flame, the burner comprising: a fuel conduit having a nozzle end; a primary oxidant conduit having a nozzle end positioned below the fuel conduit; a secondary oxidant conduit having a nozzle end positioned above the fuel conduit; a primary oxidant delivery system for delivering the primary oxidant to the primary oxidant conduit at a pressure which causes the primary oxidant to exit the primary oxidant nozzle end at a supersonic velocity; and a secondary oxidant delivery system for delivering the secondary oxidant to the secondary oxidant conduit at a pressure which causes the secondary oxidant to exit the second oxidant nozzle end at less than a supersonic velocity.

2. The burner of claim 1, wherein the primary oxidant exits the primary oxidant nozzle end at about 300 m/s to about 500 m/s.

3. The burner of claim 2, wherein the secondary oxidant exits the secondary oxidant nozzle end at less than about 100 m/s.

4. The burner of claim 2, wherein the fuel exits the fuel nozzle end at about 50 m/s to about 200 m/s.

5. The burner of claim 1, wherein the primary oxidant delivery system delivers about 20 percent to about 50 percent of the oxygen required for stoichiometric combustion.

6. The burner of claim 1, wherein the secondary oxidant delivery system delivers about 50 percent to about 80 percent of the oxygen required for stoichiometric combustion.

7. The burner of claim 1, wherein the fuel conduit, the primary oxidant conduit, and the secondary oxygen conduit are configured to inject the fuel and oxidants in substantially horizontal parallel jets.

8. The burner of claim 1, wherein the secondary oxidant is air.

9. The burner of claim 1, wherein the secondary oxidant is delivered through a plurality of secondary oxidant nozzles.

10. The burner of claim 1, wherein the primary oxidant conduit includes a converging-diverging nozzle at the nozzle end.

11. The burner of claim 1, wherein the primary and secondary oxidant delivery systems are configured to deliver the primary and secondary oxidants at variable velocities which allow the flame characteristics to be varied according to the needs of a particular furnace.

12. An oxy-fuel burner for producing a long, luminous flame, the burner comprising: a fuel conduit having a nozzle end; a primary oxidant conduit having a nozzle end positioned below the fuel conduit; a secondary oxidant conduit having a nozzle end positioned above the fuel conduit; a fuel delivery system for delivering the fuel to the fuel conduit at a pressure which causes the fuel to exit the fuel nozzle end at a first velocity; a primary oxidant delivery system for delivering the primary oxidant to the primary oxidant conduit at a pressure which causes the primary oxidant to exit the primary oxidant nozzle end at a second velocity; a secondary oxidant delivery system for delivering the secondary oxidant to the secondary oxidant conduit at a pressure which causes the secondary oxidant to exit the second oxidant nozzle end at a third velocity, wherein the second velocity is greater than the first and third velocities.

13. The burner of claim 12, wherein the second velocity is a supersonic velocity.

14. The burner of claim 13, wherein the second velocity is about 300 m/s to about 500 m/s.

15. A method of generating a flame suitable for float glass furnaces, the method comprising: injecting a fuel through a centrally located nozzle in a refractory burner block; injecting a primary oxidant at supersonic velocity below the fuel; and injecting a secondary oxidant above the fuel nozzle at a lower velocity than the primary oxidant.

16. The method of claim 15, wherein the primary oxidant is injected at about 300 m/s to about 500 m/s.

17. The method of claim 15, wherein the primary oxidant is at least 30% oxygen and the secondary oxidant is less than 30% oxygen.

18. The method of claim 15, wherein the secondary oxidant is injected at less than about 100 m/s.

19. The method of claim 15, wherein the fuel is injected at about 50 m/s to about 200 m/s.

20. The method of claim 15, wherein the injection of the primary oxidant supplies about 20% to about 50% of the oxygen required for stoichiometric combustion.

21. The method of claim 15, wherein the fuel, primary oxidant, and secondary oxidant are injected substantially horizontally.

22. A method of generating a long, luminous flame, the method comprising: injecting a fuel through a centrally located nozzle in a refractory burner block; injecting a primary oxidant containing at least 50% oxygen below the fuel at a first velocity; and injecting a secondary oxidant containing less than 30% oxygen above the fuel at a second velocity which is less than the first velocity.

23. The method of claim 22, wherein the primary oxidant is injected at about 300 m/s to about 500 m/s.

24. The method of claim 22, wherein the secondary oxidant is injected at less than about 100 m/s.

25. The method of claim 22, wherein the fuel is injected at about 50 m/s to about 200 m/s.

26. The method of claim 22, wherein the injection of the primary oxidant supplies about 20% to about 50% of the oxygen required for stoichiometric combustion.

FIELD OF THE INVENTION

The invention relates to a burner for a furnace, and more particularly, the invention relates to an oxygen-fuel fired burner with adjustable flame characteristics for a high temperature furnace, such as a float glass furnace.

BACKGROUND OF THE INVENTION

Increasing demands for flat glass (produced in float glass furnaces) all over the world is expected to become the major driving force for improved burner technology for float glass furnaces. The float glass industry is expected to see pressure to reduce emissions levels particularly in some geographic areas where new emission standards are being set. One way to improve efficiency of furnaces is to switch from air-fuel fired burners to oxygen-fuel (oxy-fuel) fired burners. The reduced NOx and particulate emissions demonstrated in the container and fiber glass industries after incorporating oxy-fuel technology, along with the improved glass quality and fuel savings are attractive to the float glass industry. However, there are significant difficulties in incorporating oxy-fuel technology into float furnaces.

Typical float furnaces are side-fired, air-fuel fired regenerative types with five to eight ports per side.

The flame length is probably the most important consideration in the operation of a side-fired regenerative furnace

Oxy-fuel burners have been used for many years in the glass industry in general especially in the fiberglass, TV glass, and container glass industry segments. Until recently, the float glass industry has avoided oxy-fuel fired burners due to cost reasons. However, oxygen firing in float glass furnaces is common for oxygen boosting. For example, small amounts of oxygen may be delivered from one or more oxygen boost burners

There are few complete oxy-fuel fired float furnaces in the operation today and they have been using retrofit oxy-fuel burners designed specifically for smaller container or fiberglass furnaces. These conversions were most likely made to meet emissions standards.

Known oxy-fuel burners are predominately nozzle mix designs and avoid premixing for safety reasons due to the increased reactivity of using oxygen as the oxidant versus air. Some common designs of nozzle mix oxy-fuel burners are described in U.S. Pat. Nos. 5,199,866; 5,490,775; and 5,449,286. The concept of nozzle mix oxy-fuel burners is to mix fuel and oxygen at the burner nozzle. These burners can include single or multiple nozzles for fuel and/or oxygen. The flame produced is a diffusion flame with the flame characteristics determined by mixing rates. Short intense flames are most common with these burners, however some delayed mixing geometry are considered to generate longer luminous flames.

Another more recent burner type used in the glass industry for melting applications is the “flat flame” burner. These are multi-orifice burners with various geometries that can produce a flame that is 2 to 3 times wider than a traditional (cylindrical) oxy-fuel flame. U.S. Pat. Nos. 5,545,031; 5,360,171; 5,299,929; and 5,575,637 show examples of flat flame burners.

Most commercial oxy-fuel burners are unsuitable for use in float glass applications because of the shorter overall flame length and lack of air firing ability. It would be desirable to provide the emissions benefits of an oxy-fuel fired burner with a long, luminous, stable flame needed for float glass furnaces. It would also be desirable to provide an oxy-fuel fired burner for a float glass furnace with an adjustable flame temperature profile.

SUMMERY OF THE INVENTION

The present invention relates to an oxy-fuel burner with a long, luminous, stable flame suitable for use in a float glass furnace.

In accordance with one aspect of the present invention, an oxy-fuel burner for producing a long, luminous flame includes a fuel conduit having a nozzle end, a primary oxidant conduit having a nozzle end positioned below the fuel conduit, and a secondary oxidant conduit having a nozzle end positioned above the fuel conduit. A primary oxidant delivery system delivers the primary oxidant to the primary oxidant conduit at a pressure which causes the primary oxidant to exit the primary oxidant nozzle end at a supersonic velocity. A secondary oxidant delivery system delivers the secondary oxidant to the secondary oxidant conduit at a pressure which causes the secondary oxidant to exit the second oxidant nozzle end at less than a supersonic velocity.

In accordance with an additional aspect of the present invention, an oxy-fuel burner for producing a long, luminous flame includes a fuel conduit having a nozzle end, a primary oxidant conduit having a nozzle end positioned below the fuel conduit, and a secondary oxidant conduit having a nozzle end positioned above the fuel conduit. A fuel delivery system delivers the fuel to the fuel conduit at a pressure which causes the fuel to exit the fuel nozzle end at a first velocity. A primary oxidant delivery system delivers the primary oxidant to the primary oxidant conduit at a pressure which causes the primary oxidant to exit the primary oxidant nozzle end at a second velocity. A secondary oxidant delivery system delivers the secondary oxidant to the secondary oxidant conduit at a pressure which causes the secondary oxidant to exit the second oxidant nozzle end at a third velocity. The second velocity is greater than the first and third velocities.

In accordance with a further aspect of the invention, a method of generating a flame suitable for float glass furnaces includes the steps of injecting a fuel through a centrally located nozzle in a refractory burner block, injecting a primary oxidant at supersonic velocity below the fuel, and injecting a secondary oxidant above the fuel nozzle at a lower velocity than the primary oxidant.

BRIEF DESCRIPTION OF THE DRAWING FIGURES

The invention will now be described in greater detail with reference to the preferred embodiments illustrated in the accompanying drawings, in which like elements bear like reference numerals, and wherein:

DETAILED DESCRIPTION OF THE INVENTION

An oxy-fuel burner

The supersonic speed of the primary oxidant jet creates massive entrainment of furnace gas in the axial direction of the flame. This entrainment of furnace gases provides dilution of the flame gases reducing the flame temperature and increasing the flame length. The sub-stoichiometric combustion between the primary oxygen jet and fuel jet create a very low temperature flame diluted with furnace gases and containing soot particles resulting from thermal cracking of excess fuel.

As shown in

The oxy-fuel burner configuration of

On the other hand, the flat flame oxy-fuel burners while generating a wider flame do not have sufficient flame length to deliver heat into the large width of a float glass furnace. In addition, the flat flame burners do not have adjustability features (flame length control) to allow the flame characteristics to be altered depending on the furnace size, changes in pull rate, reducing emissions, and providing the most important characteristics that is flame temperature control along the flame length. In addition, most flat flame oxy-fuel burners are designed for oxygen gas having a purity of 90% and greater. In contrast, the oxy-fuel burner of the present invention can use air as the secondary oxidant providing up to about 80 percent of the required oxygen, thus reducing the overall operating cost of melting without compromising performance.

The solution provided by the present invention is to delay the mixing of the fuel and oxidant, diluting the fuel and oxidant using massive flue gas entrainment, and using secondary oxidant (air or low purity oxygen) to complete combustion with extremely long and low NOx flame. The new oxy-fuel burner

The preferred dimensions for the burner

The burner block

The fuel for use in the present invention may be any of the normally gaseous fuels including, but not limited to, methane, natural gas, propane, hydrogen sulfide, and the like, as well as liquid fuels, such as fuel oils, heating oils, waste oils, slurries, and the like. The “primary oxidant” for use in the present invention is any gaseous oxidizer having at least 30% oxygen, and preferably 50%-99.99% oxygen. The “secondary oxidant” for use in the present invention is any gaseous oxidizer having at least 10% oxygen, and preferably less than about 50% oxygen, such as air or oxygen enriched air.

The primary oxidant is injected at supersonic velocity, preferably about 300 m/s or greater, and more preferably about 300 m/s to about 500 m/s. The secondary oxidant (preferably air) is injected at a subsonic velocity, preferably about 30 m/s to about 100 m/s, and more preferably about 20 m/s to about 50 m/s. The typical fuel velocity is in the subsonic range, preferably about 50 m/s to about 200 m/s.

The fuel and oxidant streams can be at ambient temperature or preheated using flue gas heat recovery. The preheat level for either oxidant stream (primary or secondary) can be from about 300° F. to about 3000° F. while the preheat temperature for natural gas is limited to about ambient to about 800° F. Preheat temperatures for other fuels are limited to known acceptable temperatures.

The oxy-fuel burner

As shown in

In the case of fuel oil firing, a single fuel oil atomizer (not shown) is inserted in the fuel conduit

In order to demonstrate the effectiveness of the present invention, the fundamental characteristics of a turbulent free jet exiting from a nozzle

This principle is applied in the burner

As shown in

The amounts of furnace gas entrained by the primary oxygen jet

In the oxy-fuel burner configuration illustrated in

In the proposed burner the use of oxy-fuel combustion for entrainment of furnace gases and the use of staged combustion with secondary oxidant (air or low purity oxygen) allow maximum entrainment efficiency. Due to higher flame speeds for the oxy-fuel flame of the present invention which is about 10 times higher than for air-gas combustion, the entrainment efficiency is much higher. The resulting oxy-fuel flame (at substoichiometric conditions) powered by a supersonic jet has a much lower flame temperature at a given cross section than an air-fuel flame. The flame diluted with furnace gases also delays fuel combustion and thus produces a much longer flame length.

In the present invention, with the separate injection design of fuel and oxidant, the fuels can be preheated using the waste heat discarded up the flue. By recovering the waste heat from the flue gases the oxidant and the fuel can be preheated.

One example of a nozzle arrangement for a total power of 4 MW has following dimensions:

Primary oxygen: 20 psig to 100 psig pressure drop and the nozzle diameter of 0.5 inches.

Secondary oxidant (low purity oxygen) delivered through 3 nozzles: 0.1 psig pressure drop and nozzle diameter of 1.25 inches diameter.

Natural gas: 1 psig pressure drop and nozzle diameter of 1.25 inches.

While the invention has been described in detail with reference to the preferred embodiments thereof, it will be apparent to one skilled in the art that various changes and modifications can be made and equivalents employed, without departing from the present invention

new hybrid furnace combines air-fuel and oxy-fuel technologies to provide improved quality, productivity and fuel efficiency compared to conventional glass melting processes.

|

|

Air-Fuel Benefits

The biggest advantage of air-fuel combustion is that air is available at a low cost. As shown in Figure 1, the use of heat recovery allows air-fuel systems to be fairly efficient, considering that 80% of the air is inert.

Another key advantage to air-fuel systems is the operational experience that has been built up over many furnace campaigns. Recurring problems have been solved, and refractory performance and characteristics are well understood. As furnaces become larger and campaign targets get longer, this know-how plays an important role in minimizing risk.

Additionally, some glassmakers have reported increased foam in the refining area when using oxygen compared to using air-fuel. Whether more foam is formed with oxygen firing, or the higher velocities of the air-fuel combustion gases combined with the constant switching of firing from one side to the other simply break up the foam more effectively, is not clear. Foam acts as an insulator, which reduces heat transfer to the glass and potentially increases refractory temperatures and crown wear.

Oxy-Fuel Benefits

As discussed previously, oxygen combustion is more efficient than air-fuel because of the elimination of nitrogen. Air-fuel efficiencies can be increased by using recuperators and regenerators, but this adds costs, maintenance requirements and complexity to the glassmaker's operation, and efficiencies still fall short of full oxy-fuel furnace operations. The higher efficiency of oxy-fuel leads to fuel savings, which can be a significant driver with today's high fuel costs.

Another advantage of oxy-fuel is the simplicity of the combustion system. Heat recovery is typically not used because of the much lower heat losses to be recovered. This eliminates problems with regenerators and recuperators such as blockage of ports (particularly near the batch charger), checker collapse, uneven flow rates and reduced campaign life. In addition, oxy-fuel systems fire at a continuous rate, controlled by the glassmaker without interruption. The benefit can be clearly seen from the stable batch patterns achieved in oxy-fuel furnaces when compared to air-fuel furnaces.

Oxy-fuel burner technology has delivered impressive gains in productivity and glass yields. Numerous articles have been published about production increases and yield improvements when converting a furnace from air-fuel to oxy-fuel combustion.1,2 State-of-the-art flat flame burners** have shown significant improvements in melt rates and glass quality. By maximizing the radiation achieved, spreading it over a large flame area and directing it down to the melt, the batch is melted more quickly, using less fuel. The size of the refining zone and the residence time for glass in that zone are both increased, with the net result being extra production and higher quality. In any economic evaluation, these two factors are vitally important and provide a significant advantage to the glassmaker.

The environmental benefits of oxy-fuel are often the main drivers for converting to this technology. By virtually eliminating nitrogen from the furnace, NOx levels can be exceedingly low with proper furnace design and burner selection. Reductions of 10-20 times compared to regenerator furnaces have been demonstrated. Additionally, the quicker melting and the lower gas velocities, combined with different flue arrangements, mean that far less batch is blown out of the furnace, thus reducing losses, handling costs and emissions. Batch carryover into the early ports of regenerative furnaces is one of the biggest ongoing challenges for glassmakers operating with air-fuel combustion systems.

Float furnaces offer a special case for oxygen supply. The tin bath used for forming the glass ribbon needs large quantities of nitrogen to prevent the tin at the surface from oxidizing. When the decision is made to convert the furnace to oxy-fuel, an air separation plant can be designed to produce both oxygen and nitrogen more efficiently than supplying each gas individually.

**The Cleanfire® HRTM burner, supplied by Air Products and Chemicals, Inc., is one example of the flat-flame technology.

Combining the Best of Both Technologies

|

Improved Glass Quality

Using oxygen in the melting zone maximizes the melt rate and fuel efficiency. The perennial problem of plugging uptank ports, or plugging and/or collapsing the uptank checker brick due to batch material carry-over in air-fuel operations, is also eliminated when oxy-fuel firing is used in this region of the furnace. The continuous firing in the melting area delivers stable batch patterns, and because the batch melts early, the refining section is effectively made larger. This expansion of the refining zone increases glass particle residence times, leading to higher-quality glass.

Additionally, because the downtank energy in the hybrid operating system is provided through air-fuel combustion, larger volumes of oxidizer and fuel are present in this region of the furnace. The higher volume of air-fuel combustion gases (required to deliver the same heat compared to oxy-fuel) can be used to more effectively spread the heat release in this critical area of the furnace, thereby minimizing one potential source of foam formation-localized overheating of the glass. While the stability of the oxy-fuel system in the melting area helps deliver good quality (via batch pattern and convection current control), paradoxically it can be the inherent instability of the regenerator system in the refining zone-with the variation of flame temperatures, periods with no firing and the reversal of the flames-that further minimizes foam and improves glass quality. Furnace trials conducted by Air Products have shown the effectiveness of air-fuel and air-oxy-fuel systems in breaking up foam in oxy-fuel furnaces.<

|

As outlined earlier, "available heat" is the energy that is available to the process when the energy lost in the flue gases is accounted for. The available heat curve shown in Figure 4 highlights one of the key drivers for the hybrid furnace concept. It is the first amounts of oxygen added that deliver the biggest increase in available heat and therefore deliver the biggest increase in efficiency. For this temperature, transitioning from air at 21% oxygen to a 60% oxygen enrichment level increases the available heat from 46 to 70%, providing 52% more heat to the process. Going from 60% enrichment to 100% oxygen increases the available heat from 70 to 75%, only adding 7% more heat for a similar change in enrichment level.

Often, solutions developed for one industry can be customized and fine-tuned to solve problems in another field. For example, the variation of available heat is widely understood in many industries such as aluminum melting, where highly efficient rotary furnaces use complete oxy-fuel combustion systems because they can absorb all the heat effectively. Within this same system and often at the same site, reverb (rectangular, stationary) type furnaces use air-oxy-fuel combustion systems because heat transfer to the bath is not quick enough to fully absorb the heat available from full oxy-fuel. By matching the heat input to the inherent efficiency of the process, these manufacturers use the optimal amount of oxygen. The reverb furnace operators achieve lower overall costs and use less oxygen using a combination of air-fuel and oxy-fuel combustion than they can achieve with full oxy-fuel.

In glassmaking, low levels of enrichment, such as with oxy-boost systems, are an established example of delivering significant benefits with only about 10% of the total furnace heat input. The operation is optimized to deliver the maximum glass production benefit, while minimizing the investment capital and power requirements of the oxygen supply. The hybrid concept is really a matter of using just the right amount of oxygen for the application—no more, no less.

Economic Considerations

A detailed economic model for various glass making technologies has shown excellent correlation with data from air-fuel, oxy-fuel and oxy-fuel boosted air-fuel furnaces. The results from the model indicate that significant savings can be achieved using the hybrid melting technology. The model includes capital costs such as refractories and labor for constructing the furnace and heat recovery system, as well as the costs associated with the time required for a rebuild, which is often shorter for a hybrid system. Operating costs, production levels, fuel usage and glass yields are also accounted for in detail.

The economic model has also shown that the hybrid melter provides big benefits when applied to a crippled furnace. The hybrid technology provides heat input where it is most effective-right above the glass-without modifications to the furnace walls or crown. The model projects savings of $5 to $12 per ton of glass for installations, assuming a production increase of 5-10% and improved yields of 1-2%. Greenfield site installations also show economic benefit when compared to air-fuel, and become all the more attractive when typical end-of-campaign issues are factored in.

Filling the Gap

Hybrid glass melting might not be the right choice for every situation, but it represents another option to consider. Compared to air-fuel operations, the hybrid technology can deliver fuel savings, production increases, yield improvements, furnace life extension, emissions reduction and more consistent performance throughout the furnace campaign. Compared to either air-fuel or oxy-fuel operations, the technology can deliver lower-cost, higher-quality glass.

Furnaces have been operated with air-fuel combustion systems for thousands of years. This long track record has established familiarity and considerable operating know-how in its favor, compared to the relatively new oxy-fuel based technologies. The hybrid technology fills the gap between air-fuel and oxy-fuel operating systems, delivering the best of both technologies.

For more information about the hybrid glass melting furnace, contact Air Products and Chemicals, Inc., 7201 Hamilton Blvd., Allentown, PA 18195; (610) 481-7007; fax (610) 481-5136; e-mail lievreka@apci.com ; or visit http://www.airproducts.com .

References

1. 1. Lindig, M.R., "TV Oxy-Fuel Conversion and Experience with Noncatalytic Denitrification," in Proceedings of the 59th Conference on Glass Problems, The American Ceramic Society, Westerville, OH, 1999, pp. 37-45.

2. Eleazer, P.B., and Slavejkov, A.G., "Clean Firing of Glass Furnaces Through the Use of Oxygen," in Proceedings of the 54th Conference on Glass Problems, The American Ceramic Society, Westerville, OH, 1994, pp. 159-174.

3. Hoke, Bryan C. Jr.; D'Agostini, Mark D.; Slavejkov, Aleksandar G.; Lievre, Kevin A.; and Horan, William J., "Goodbye LOX?" Ceramic Industry, April 2000.

http://www.ceramicindustry.com/Articles/Feature_Article/d54ba81998ac7010VgnVCM100000f932a8c0____

Low-Emissivity Coating Glass

Low emissivity coating glasses are manufactured through coating several layer of metal oxide films on high quality SGG transparent float glasses or tint glasses by the means of vacuum magnetism control and cathodic sputtering. Through different kinds of combination of metal oxide films, low emissivity coating glass is of good selection towards spectrum. It is able to received of great deal of near infrared and visible light to assure the brightness indoors. It can also prevent medium infrared an far infrared produced by heat source radiation. Thus, in hot summer, it is able to prevent the slolar radiation heat from entering the buildings to assure cool indoors; and in cold in winter, it is able to made the radiation heat of air-conditioners and warming apparatus reflected indoors, but not get out of the buildings through paaing common glasses. Therefore, its good heat insulation performance can save the energy consumption of buildings greatly.

Note: In the engineering research field of low emissivity coating glass, French Saint-gobain Group is a global authority in the world today, Saint-gobain Group was established in France in 1665. At present, it has become the largest manufacture of building materials. In the industry of glass, it ranks the third place globally. Besides, Saint-gobain Group is one of the top 500 powerful enterprises < it was ranked in the 105th place in 2005>

advantages of Low-Emissivity Coating Glass:

Most of the original glass sheets of the low emissivity coating glasses provided by our company to the customers are from Saint-gobain Group. At present, the low emissivity products of our company include SGG PLANITHERM new-generation low emissivity glasses and SGG COOL-LITE KT low emissivity solar control double-function glasses.

Compared with traditional low emissivity coated glasses, SGG PLANITHERM and SGG COOL-LITE KT have the following advantages:

1. Through different combination of various films, they have more prominent thermal insulation performances and are able to realized warm in winter and cool in summer;

2. The films are firm, able to be bent and toughened. Both GSS PLANITHERM and SGG COOL-LITE KT are off-line low emissivity glasses. Due to their peculiar coating technology, the low emissivity glass sheets can be transported to the glass production base of our company for deep processing of flat toughening, bent toughening, hollowing and doubling to ensure rapid supply and services;

3. Suitable permeation rate of visible light is able to keep the indoors bright and comfortable, not dizzy in summer and limpid in winter;

4. Very low rate of glister is able to reduce light pollution.

Besides, in order to satisfy the requirement of different customers, our company also sells on-line low emissivity glasses.

.: Weblog Themes By Pichak :.